Engineer

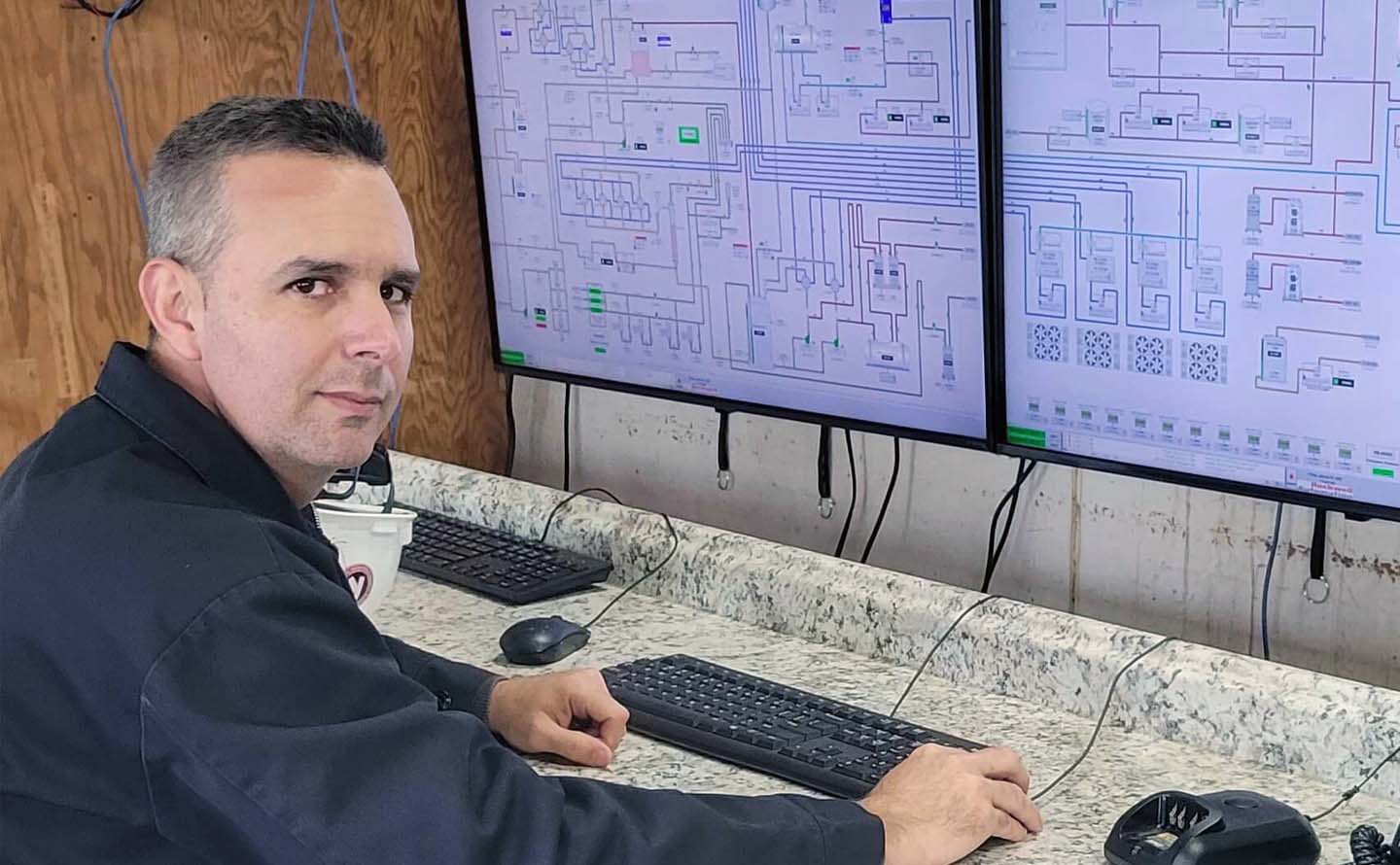

Maykel Alvarez

Kuehne Company is blessed to have so many brilliant engineers who help keep all three plants running safely and efficiently. One such engineer is Maykel Alvarez, an Electrical Engineer who has been working with the company since 2015.

Last February, Maykel was promoted from I&E Technician to his current position, from which he began phase 1 of a project to convert the legacy side of our manufacturing facility from an Analog Control System to a Programmable Logic Control System (PLC).

PLC Project Phases

Maykel began by creating documentation of how the entire design functions – this was Phase 1. Next, for Phase 2, he designed all the junction boxes and ran wires from the PLC to the field. He and his team connected all the wires and started running the new system, but had to be careful to also keep the old system running at the same time.

Phase 3 will entail getting chlorine stations, a new caustic railroad track, bleach storage tank, loading trucks, and a railroad car set up to be controlled by the PLC. Maykel is highly organized and will be sure to have final documentation for the new system, which will include the creation of a Process Indication Diagram, which is like a blueprint of the entire process.

Maykel proudly states that Kuehne will not need to hire any outside help to complete this project. Thus far, the work has been successfully completed primarily by himself and his team of 2 other I&E technicians, Mr. Austin Wilkes and Mr. Joe Almeida.

Benefits of the New System

Manny Correia, Kuehne’s Chlor Alkali Hypochlorite Technologist, explains why Maykel’s work is so important: “Maykel’s most recent efforts have greatly improved the overall operation of the NJ facility’s legacy (liquid manufacturing and chlorine repackaging) processes. These control systems make operating these processes safer by increasing an operator’s ability to visualize various flows, temperatures, and reactions within illustrations and animations on several computer monitors. This enhancement provides the operators more time to make adjustments as necessary and can even be operated from within the Brine to Bleach (BTB) Control Room.

Innovating for Safety

As Maykel showed me some of the new features of the new system, he pointed out various ways that it improves safety by reducing human error. For example, the new system will not allow someone to add to a tank that is already full. Additionally, loaders can now load trucks through the PLC, as opposed to manually turning valves.

Manny Cunha, Kuehne’s Chlor Alkali Hypochlorite Technologist, is especially enthusiastic about Maykel’s project. He says “When it comes to Process Control design and programming, Maykel does it in a very innovative, creative, and efficient manner. He always has a good logical way to get things done.”

Maykel states that he “would like to see Kuehne move forward with technology in all three locations.” Kuehne is listening to valuable employees like Maykel who are pushing further innovations in our technology. Multiple departments are currently working together to implement new technology, and we plan to continue this trend.

Working with Maykel

Kevin Booth, our Director of Corporate Engineering, has a lot of great things to say about Maykel:

“When I think of Maykel I see a lot of myself. Maykel is a quiet and shy person who goes about his daily business without looking for a pat on the back for his valued contributions.

After joining the engineering team, Maykel was tasked with adding the Legacy process to the PLC Control System. With not much input from me, Maykel coordinated the transfer of I/O with Operations and Maintenance such that now at the Scale House and the BTB control room the Legacy process can be monitored and controlled. We can now track performance and recall historical data which is also beneficial during regulatory audits. I feel comfortable allowing Maykel to handle the company’s Electrical Engineering which allows me to focus more on my role as the Director of Engineering and the positions responsibilities.”

Manny Correia adds to this by stating that “Maykel is a pleasure to work with. He is calm, collected, and never gives up on solving a particular problem. Maykel not only has a deep understanding of the facility’s instrumentation systems, but one can clearly see he has an appreciation and passion for their operation.” He goes on to say that “much like Kevin Booth, Maykel can talk the talk and walk the walk!”

Family Matters

Family is another one of Maykel’s passions, and he is grateful that he is able to spend time with the ones he loves.

In his free time, Maykel enjoys celebrating life together with his wife and child. He also gets to spend a lot of time with his grown daughter and her baby – Maykel’s first grandchild!

Maykel enjoys cooking too and knows how to make delicious Cuban foods like chicharrones (pork rinds).